Manure: A Wartime Fertilizer

The Future Begins Now for Working Cattle

Ticks, Fleas and Other Uninvited Farmyard Companions

Testing the Trace Harness

by Jim Quade of Roundup, MT

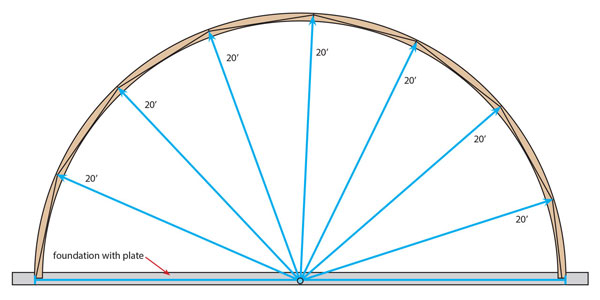

First you must decide what size of building you want, 28 – 48 feet wide and a length that is in 6 foot increments. The rafters are placed on 6 foot centers, with 2” x 4” purlins and steel siding/roofing. Let’s work with a forty foot wide foundation, easy to figure. The rafters are built out of 8 foot 1” x 8” boards. The number of 1x8s can be figured out by using the circumference. For a 40 foot wide building, figure a 40 foot diameter circle, which is 125.6 feet in circumference. Half of this circle would give you one layer of a rafter. So about 63 feet of 1×8 multiplied by 4 (because each rafter is composed of 4 layers). Each rafter then would use thirty-two 8 foot 1x8s. The end rafters really only need three layers.

Find a fairly flat area to lay out the first piece. You will need a tape measure and three 1x8s.

Mark a circular line on the board as shown, careful so the lines on both ends are very similar dimensions and the middle is 1” or a little less from the back edge. Mark out at least three boards like this. Cut these on your line with a power hand saw, try to follow the line closely to make a smooth cut.

Now it is best to have access to a radial arm saw. Set up the three outside pieces you just cut in the fashion shown on the saw table. Use an inside piece to locate the 2nd and 3rd pieces on the saw table.

Set the saw blade crossways, so when you push a board through the saw following the curved fence you just layed out on the saw table, the boards are cut just like the first three you cut by hand. If this is set up correctly the board should have a nice even curve out, only leaving the 1” or less for the middle of the back side. Cut all your boards like this for all the rafters.

The next process, which can be done as soon as the boards are run through the saw, is to take the outer piece from the back and nail it onto the front edge of the inner piece, as shown.

Now you have a curved piece for your rafter. After all the boards are run through the saw and nailed to form the curved pieces, they will need to be run through the saw again to cut the ends to a different angle. The saw is turned back to its normal crosscut position and the curved boards layed back into the curve pattern so both ends can be cut to the new angle perpendicular to the curve, so they fit together tight on the rafters.

Once the ends are all cut to their new angle you can start to lay out the rafters. If you have the foundation poured already, that works as a good place to lay out the rafter. Hopefully the sill plate is on the foundation already. Drive a nail part way in the plate right at the plate edge, hook a tape over the nail, go out 20 feet both ways from the nail and put a mark on the sill plate, this is the width of your building. Now lay a rafter board on the plate with one end even with the plate edge that has the nail in it. Support both ends of the rafter boards and keep as level as possible with the sill plate. Use the tape and make sure both ends are at 20’, continue with this until you reach the sill plate again and the mark you had previously made. Cut off any that goes past the plate.

Now you need to cover these boards with a good wood glue. Use a plastic resin type that is a powder mixed with water, or similar; a slow drying glue is better. The next layer start out with a 6 foot length of rafter board, this affects the splices by creating an offset. Nail 4 nails across every 16” using a 6d nail so it goes through both layers. Now apply glue to that layer and lay out more boards, starting this layer with a 4 foot piece and using 8d nails so they go through all three layers with similar nail pattern. Then glue again and add the 4th layer, starting with a 2 foot piece and using 10d nails so again they go through all boards using a similar nail pattern. This completes one rafter. Leave it lay making sure it is nice and level all the way around so when the glue dries you end up with a nice straight rafter.

Next lay out another layer of boards on top of the first rafter, using it as your pattern. Apply glue to the top of these boards, add another layer of boards and nail with 6d nails again. Glue again and add another layer of boards and nail with 8d nails. You can stop here on this one and use it for an end rafter because the ends have studs to help support this rafter. You will need two end rafters.

Proceed with this process until you have all the rafters made for the length of your building.

You can make 3-ply rafters and space them at 2 foot centers and cover with sheeting or boards so the building can be shingled if desired.

When spacing rafters at 6 foot centers use 2” x 4” purlins to go from one rafter to the next. The first row of purlins is nailed onto the sill plates, then a row about every 24” – 30” up the outside of the rafters, making sure there is a row at the end of the length of steel or whatever material that will be used to cover the building.

©1976 - 2024

Small Farmer's Journal

PO Box 1627 • Sisters, Oregon 97759

800-876-2893 • 541-549-2064

agrarian@smallfarmersjournal.com

Mon - Thu, 8am - 4pm pacific